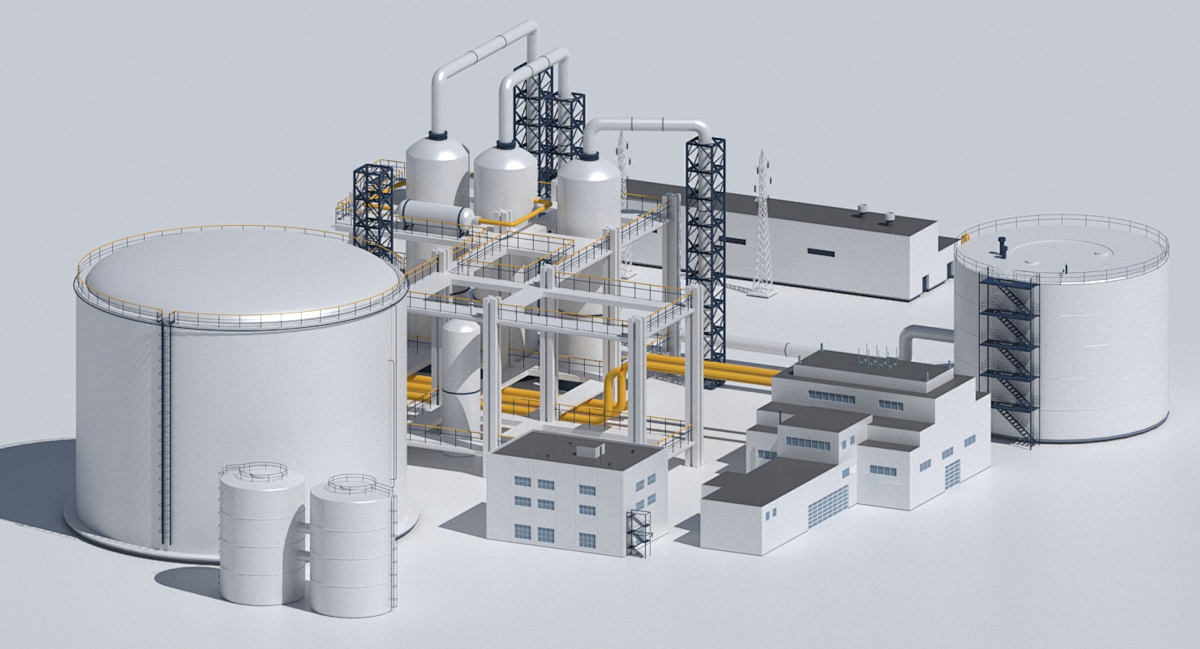

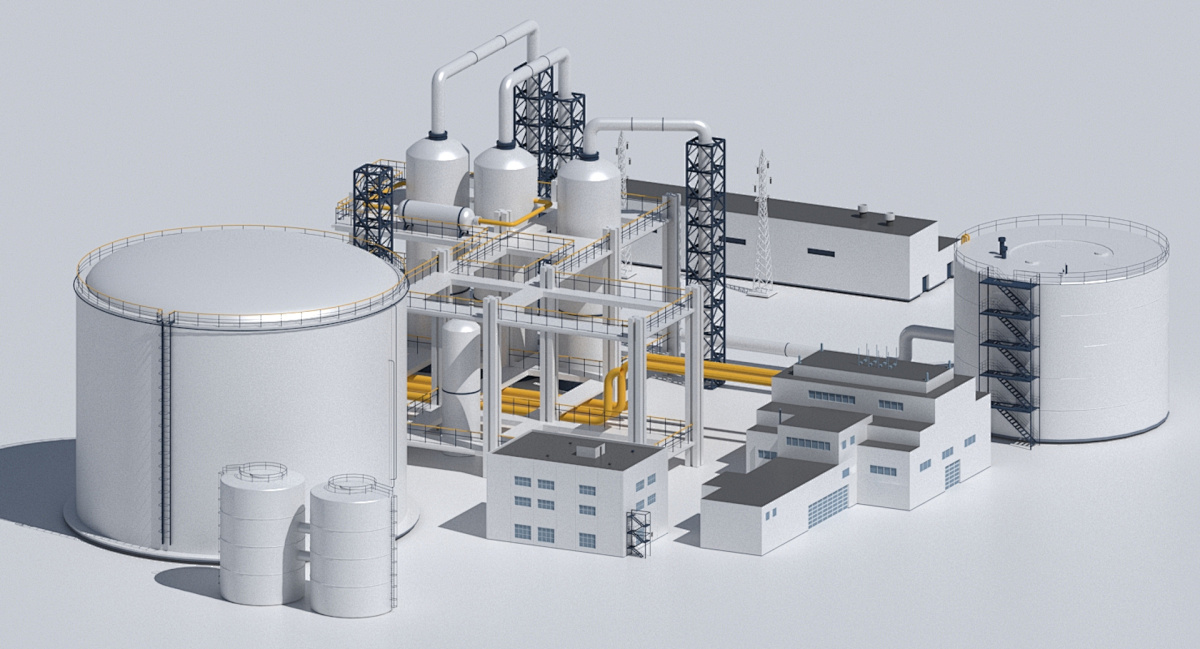

GDKY Successfully Concludes HAZOP Analysis for Small-Scale Methanol Pilot Plant in South Korea

The technical team of Gongda KaiYuan Environmental Protection Technology (Nanjing) Co., Ltd. (hereinafter referred to as "GDKY ") traveled to South Korea and successfully organized and completed a special technical meeting with South Korean HAZOP experts and the American client. Centered on the signed small-scale methanol pilot plant project, the meeting conducted in-depth discussions with Hazard and Operability Analysis (HAZOP) as the core, ultimately reaching comprehensive consensus and formulating a systematic risk control plan. This not only built a solid safety defense for the smooth progress of subsequent project phases but also demonstrated the company's technical control capabilities and cross-border collaboration strength in international cooperative projects.

During the meeting, the technical team of GDKY, together with South Korean HAZOP experts, engineers from the South Korean design institute, and representatives of the American client, focused on core documents such as the Piping and Instrumentation Diagrams (P&IDs) and operating procedures of the project. Adopting the guide word analysis method, they conducted a comprehensive review of process state parameter changes, operational deviations, and potential risks in each unit of the plant. Aiming at potential risk points in key links of the small-scale methanol pilot plant, such as precise temperature control, stable pressure regulation, and accurate material ratio, all parties conducted in-depth discussions combining their professional experience, and clearly defined the causes, scope of impact, and response measures for each risk one by one.

Relying on its profound technical accumulation in the field of green energy and chemical engineering, the GDKY team accurately put forward professional insights on process optimization and safety interlock settings for the small-scale methanol plant during the discussions, and several proposed risk control suggestions were recognized by all parties. After multiple rounds of efficient communication, the meeting finally formed a complete HAZOP analysis report, clarifying the hierarchical control plan and optimization improvement measures for various risks, which provided an authoritative and feasible technical basis for project design optimization, subsequent construction, and operation management. Representatives of the American client spoke highly of the outcomes of this meeting, stating that it effectively resolved the core safety risk issues of the project and fully reflected the professional quality and sense of responsibility of GDKY Environmental Protection. The South Korean partners indicated that this in-depth collaboration had further deepened technical mutual trust between the two sides and laid a solid foundation for future cooperation.

Please first Loginlater ~