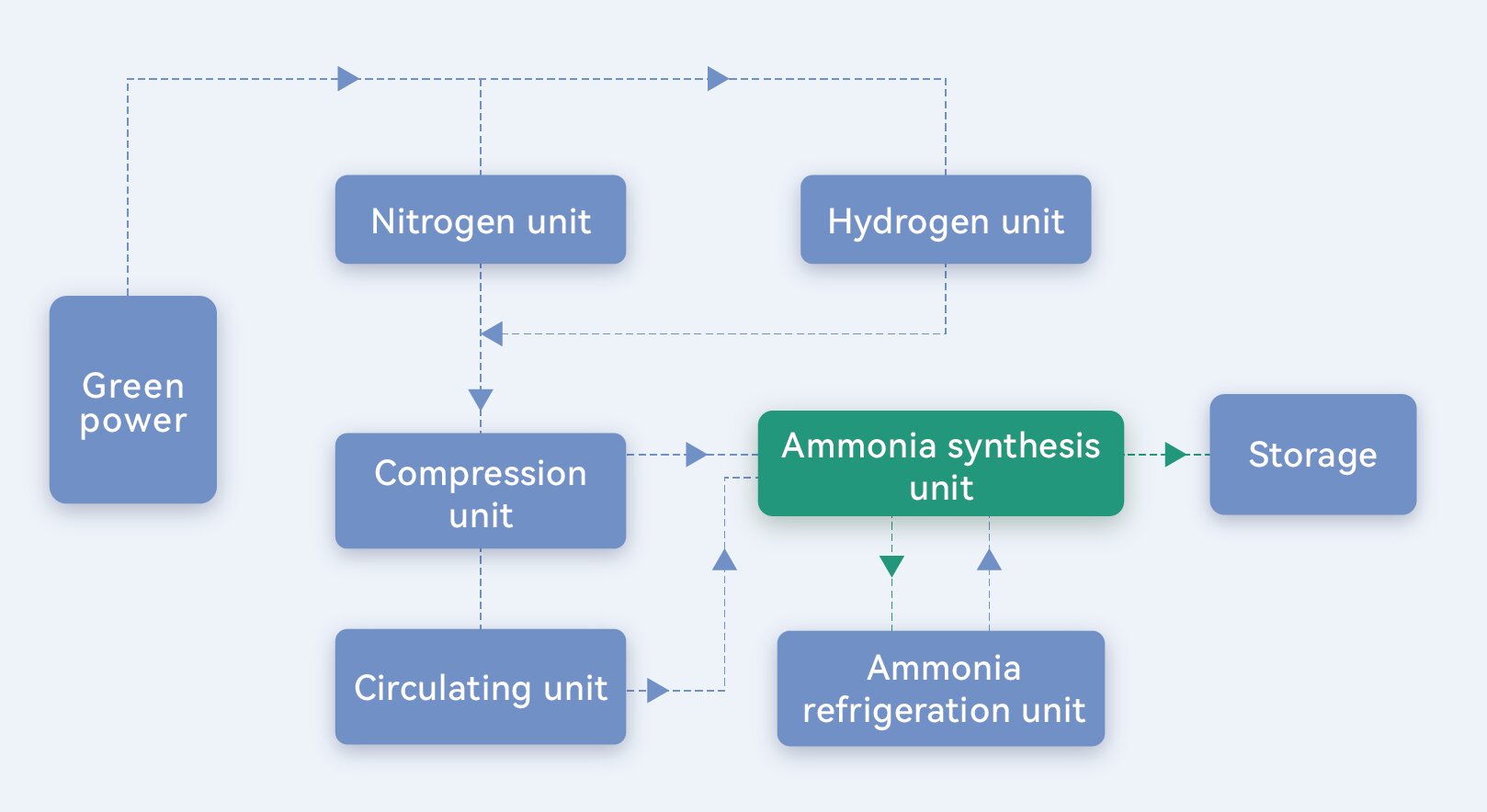

Hydrogen and nitrogen are mixed in proportion and compressed by the compressor. The compressed hydrogen and nitrogen gases enter the ammonia synthesis reactor together with the circulating gas from the outlet of the circulating machine. The mixed gas is reacted under the ammonia synthesis catalyst. The synthesis gas out the ammonia synthesis reactor is cooled by the air cooler, cold exchanger, and ammonia cooler, and then enters the high-pressure ammonia separator for liquid ammonia separation. After separating ammonia, the gas enters the cold exchanger to recover the cooling capacity and then enters the circulation machine to increase pressure, thus circulating. The liquid ammonia separated by the ammonia separator is depressurized and sent to the medium pressure ammonia separator. The flash gas is returned to the compressor for pressurized utilization, and the liquid ammonia is stored in the medium pressure ammonia separator tank.