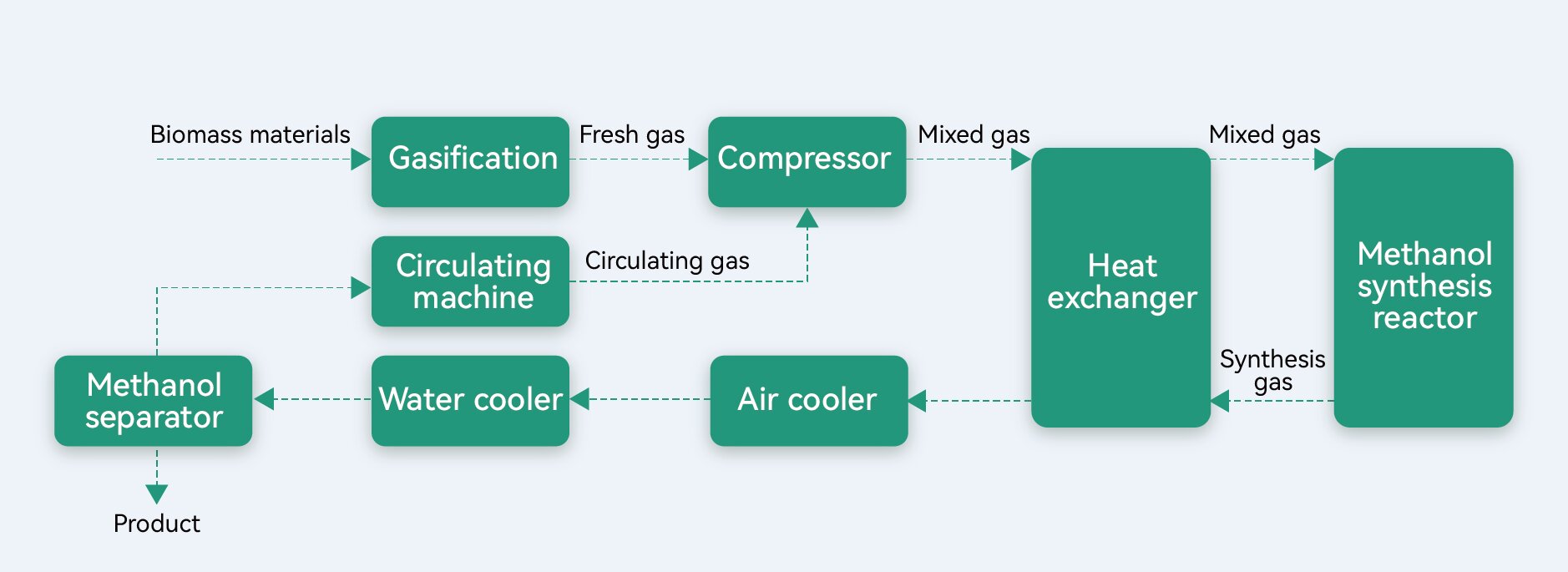

1. The fresh gas containing carbon monoxide, carbon dioxide, and hydrogen produced by biomass(or green hydrogen from water electrolyzer and CO2 from CCUS) is pressurized by a compressor and mixed with the gas at the outlet of the circulation machine. The mixed gas exchanges heat with the synthesis gas at the outlet of the methanol reactor before entering the reactor.

2. Methanol synthesis reaction is carried out in a controllable heat transfer methanol synthesis reactor. The reaction heat is removed from the bed by boiler water on the shell side and produces saturated steam as a byproduct. The gas exiting the synthesis reactor enters the heat exchanger and exchanges heat with the gas entering the reactor.

3. After heat exchange, the synthesis gas is cooled by a water cooler and enters the methanol separator for gas-liquid separation. The liquid methanol enters the flash tank for flash evaporation to obtain crude methanol.

4. The gas separated enters the circulation machine for pressurization and then mixed with fresh gas for circulation.

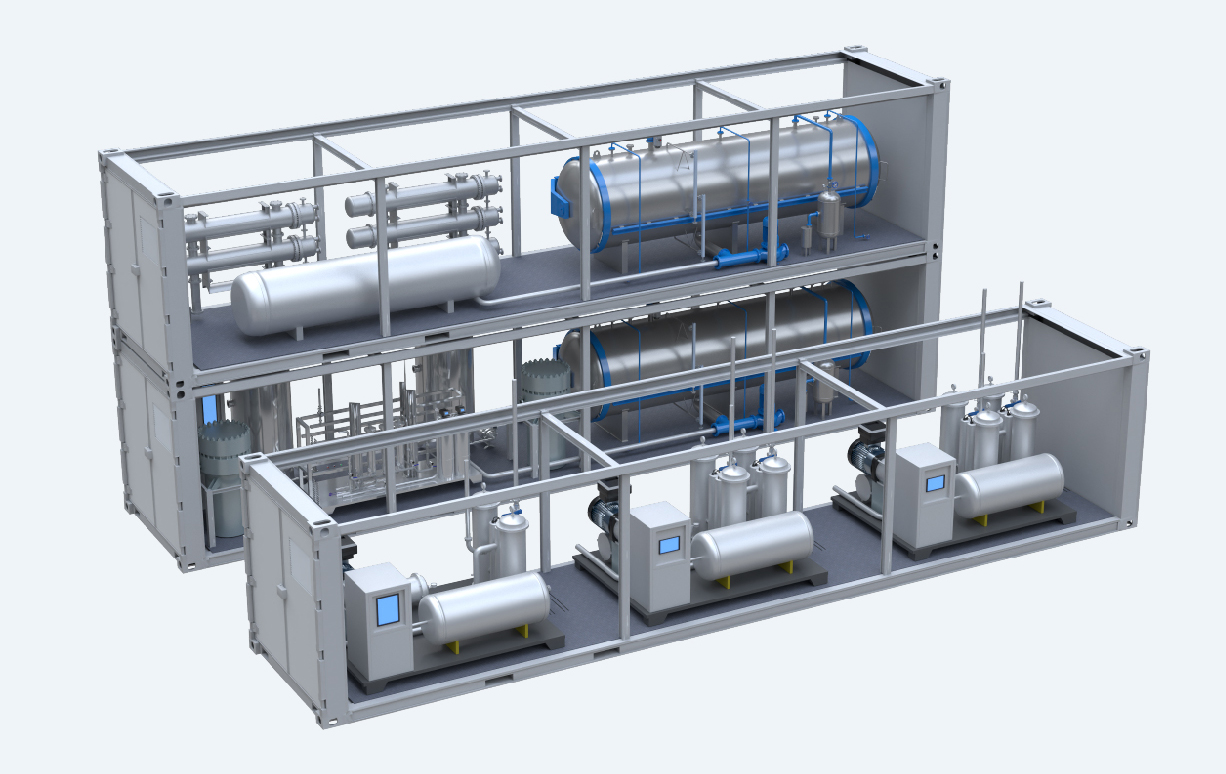

1. Revolutionary modular and containerized design: Rapid deployment, flexible expansion, strong site adaptability, and reduced investment risk

2. Embrace the essence of "green": Green raw materials, low-carbon processes, and carbon neutrality of products

3. Advanced technology and efficient integration: Core process optimization, intelligent control system, compact and efficient design

4. Wide range of application scenarios: Green shipping fuel, green chemical raw materials, energy storage carriers, distributed energy supply, circular utilization demonstration

5. Significant environmental and social benefits: Large-scale carbon reduction, promotion of renewable energy consumption, promotion of circular economy, and creation of green employment