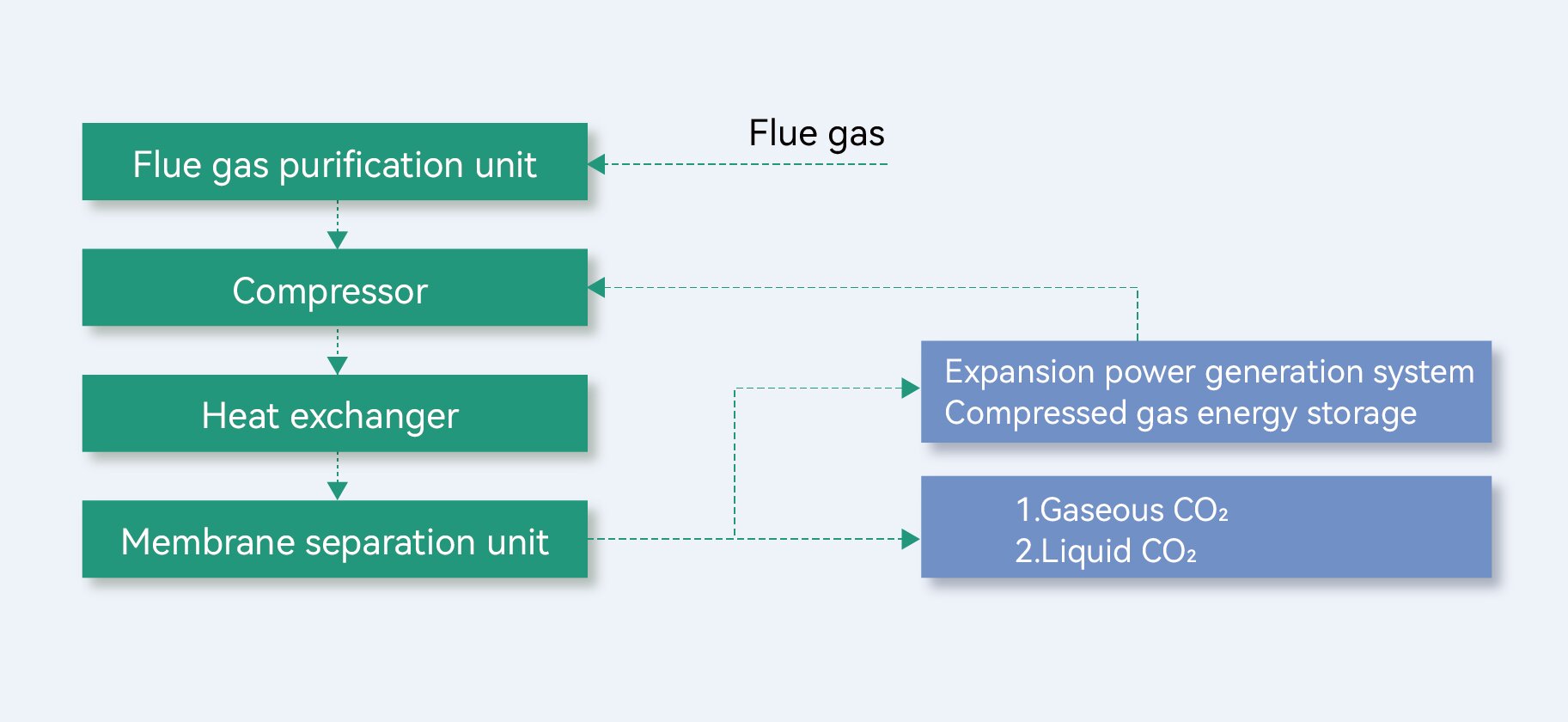

Membrane capture method: The membrane capture CO2 technology adopts high-performance membrane materials customized by Germany, combined with the integrated technology of GDKY. Under the driving force (pressure difference on both sides of the hollow fiber membrane material), the gas with relatively fast permeation rate (CO2) is enriched after passing through the membrane material, while the gas with relatively slow permeation rate, such as oxygen (O2) and nitrogen (N2), is intercepted.